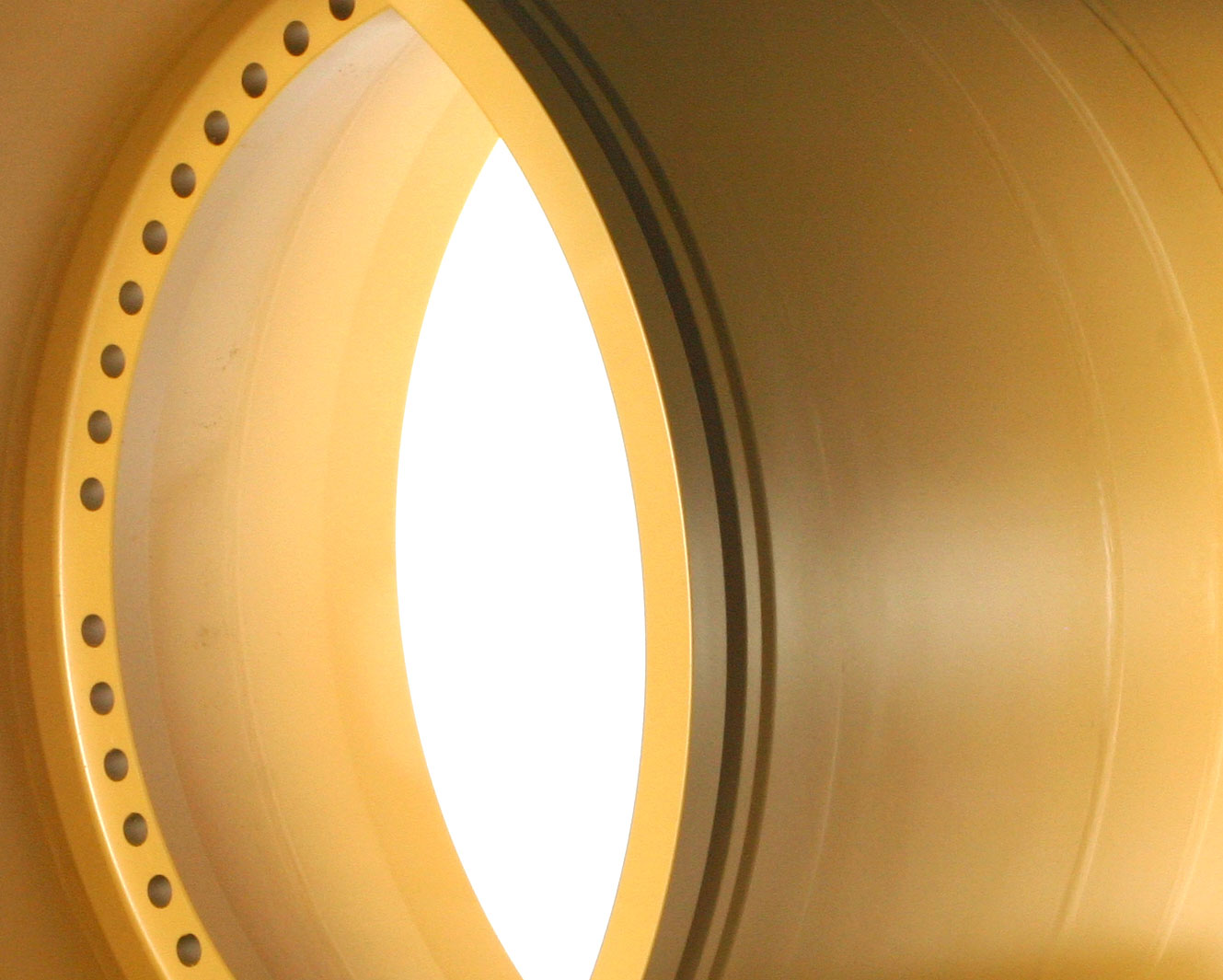

mining wheels

Mining original equipment manufacturers (OEMs) regularly improve their designs, making equipment more reliable and more productive for the harsh conditions of a mine. We work with OEMs to produce high-quality wheels that complement nearly any piece of mining equipment – including loaders and haul trucks. We're also the only global manufacturer of both wheels and tyres, which means we can offer a complete wheel assembly for your equipment designs.

manufacturing technology

wheel technology

ACCELERATED CHANGE TECHNOLOGY

Designing wheels that minimise servicing downtime is another way we help mining operations keep moving forward. Our Accelerated Change Technology (ACT) reduces downtime associated with tyre changes and rotations by as much as 50 percent. That's because it allows technicians to remove the inner tyre without having to remove the outer wheel.

Outside Vertical Mount (OVM) & Six Piece Vertical Mount (SVM)

OVM design for quick change capability allows the rim to stay attached to the vehicle during tyre change and servicing, minimising downtime and increasing safety. Used in conjunction with OVM, SVM eliminates the high-risk practice of breaking the rear bead in confined spaces using hydraulic rams.

STMT

Our Super-duty Titan Machined Taper wheel series features double lock, fully machined vertical curb and taper for precision fit between bead seat and side flange to reduce the risk of tyre damage.